All Over T-Shirt Printing Process

Want to learn more about the all over printing process at Broken Arrow? You have come to the right place! Here you'll find information on how all over shirt printing is done!

All Over Print General Requirements

With all over prints there are a few special requirements to give fantastic full print t-shirts! For starters, the t-shirts has to be 100% cotton and it prints up to one color ink. The print must be distressed near seams and hems so it will have a worn/vintage look. The maximum print size is 40" wide by 30" tall, which will span the full length and width on most t-shirts S-2X. With larger t-shirts, you may be some areas of the shirts that aren't covered by the print.

Print Size Comparisons

All Over Print Designs

Perhaps the most important part of all over shirt printing is the design! At Broken Arrow, we have a whole team of professional designers that can create the perfect all over print design just for your full print t-shirts. We have lots of samples and previous designs that you can take a look at to get ideas, but there are no boring stock designs here! Let our team of in-house artists work with your ideas to create a one of a kind design that is perfect for your all over shirt printing order. You will get an online proof to review and approve upon placing your order so you can be sure your all over print design is exactly what you had in mind. The online proof will confirm the placement, ink colors, dimensions, and will give you an approximate amount of the shirt it will take up based on shirt sizes. The same print size is used on all of the shirts in the order. If you have important information, like your company name, you'll want to be sure that information fits on the smallest shirt size so it isn't cut off on smaller sizes.

Processing the Artwork

After you have approved the proof for your all over shirt t shirts, our production department begins all of the behind the scenes work. First the artwork is processed by our team of production artists. They take care of separating the design out into colors, and creating layers of artwork that will be used to create to create the screens. Each layer of artwork is printed directly on the screen mesh, as a positive image so the image will come through correctly on the shirt during printing.

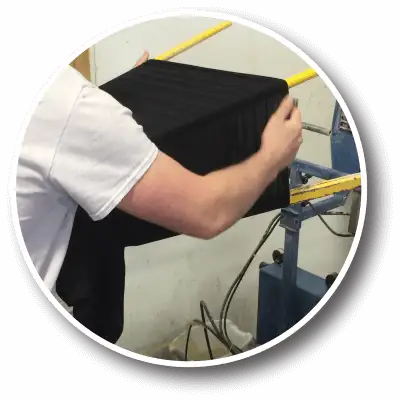

Preparing the Shirts

With all over shirt printing, the shirts are laid flat to print, without a traditional screen printing pallet between the front and back of the shirt. For optimal print results, a cornstarch adhesive is sprayed in the shirt so the front and back of the shirt sticks together during the printing process. The shirts are laid out on a wooden board with care taken to try and eliminate any wrinkles or folds in the fabric that would interfere with the all over shirt printing.

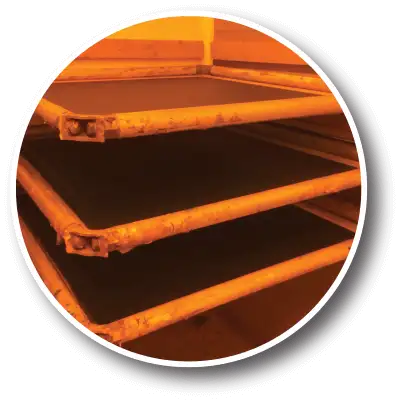

All Over T Shirt Printing

Now that the artwork is ready and the shirts are ready to go, we can begin the actual process of all over printing. Each shirt is loaded to the machine, and the shirts rotate from station to station getting each print color to create the full print t-shirts. The all over print press automatically moves the ink across the screen, depositing ink on the shirt. Once the shirt has received all of the colors, it is dried through a huge drier which cures the ink. Once the ink is cured, it will not wash off of the shirts. If there is a back print as well, the process is repeated. After the shirts have received all of the print locations, they are ready to be inspected by our quality control department, which ensures they are 100% perfect and ready to be packaged up and shipped out!

Popular Shirts for All Over Print

Gildan 2000

6.1 oz Ultra Cotton Tee

Next level 3600

Fitted Short Sleeve Crew

American apparel 2001

100% Cotton Jersey Tee

Hanes 4980

4.5oz Ringspun Cotton